MATERIALS - Blue Phoenix Sails

Main menu:

MATERIALS

OUR PRODUCTS

CLOTHES, LAMINATES AND MEMBRANES

Blue Phoenix, for the realization of the sails, whether cruising or racing, uses the materials produced by the leading companies in the market, Contender and Dimension Polyant, considering the real use of sails, combining the best characteristics of the materials proposed.

The fact that the sail maintains its draft form is a determining factor for racing sails, but it constitutes an added value for cruise sails: less heeling, better upwind performances and balanced boat at the helm.

The good quality of the material used, in fact, be it cloth or laminate, makes the owner will spend a little more, but it will be a safe investment in performance and durability of the sail.

For cruise sails the polyester (Dacron) still remains the most widely used fiber, because it has long life, it is resistant and has an affordable price.

But not all polyester fabrics are equal. Depending of the resins used and the impregnated amount, the mode of calendering and type of dressing, the different polyester fabrics vary their techniques of form and duration characteristics.

The most widely used system for cutting the polyester cloth sails is cross-cut, in panels perpendicular to the leech, because the transverse fibers (fill) in the cloth, are generally straight and of larger size than those in longitudinal (warp).

There are some particular clothes combined with other high modulus fibers (eg. Hydranet Radial or Fibercon Hybryd), made for vertical or radial cuts.

Since the advent of polyester also other extremely interesting and technical fibers have been introduced for the realization of cloths (fill and warp) and laminates (composite layer of mylar, fibers and other mylar layer, bonded and calendered) for high-technology sails , racing and offshore: Kevlar, Pentex, Dyneema, Spectra, HM Twaron, Technora aramid and Carbon.

The HM Twaron, for example, has a resistance to deformation equal to 8.5 times that of the polyester, while Dyneema, Carbon and Spectra have a resistance to deformation from 12 to 18 times that of the polyester. The use of these fibers in laminates made sails ever more efficient and lighter.

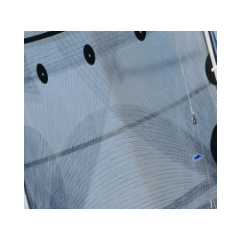

Blue Phoenix, also designs and makes membrane's sails, either for regatta (film on film) or for cruise (double taffetà), offering owners a high quality product, custom-made and guaranteed for 24 months.

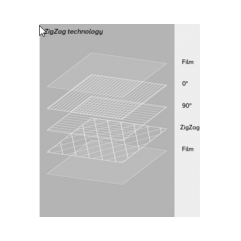

What is the Membrane?

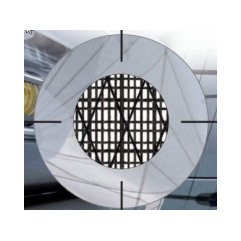

The membrane, like a laminate, is constituted by a composite layer of mylar, fibers and other mylar layer, bonded and calendered, but, unlike the laminate in which the fiber has a predetermined orientation depending on the type, in membrane, the designer establishes the shape of the fibers of each panel.

The staff Blue Phoenix, with the software Smar Azure Project, develops the project of sail size, put the fibers planning the kind of the sail, by concentrating the fibers in the major stress points and reduceing them where the sail will be less subject to stresses.

The custom project file thus obtained is sent to the manufacturers of membranes carefully selected by Blue Phoenix in order to obtain macro panels made as the plan design.

Blue Phoenix assembles macro panels, trim the sail as the project and proceeds with the finishes.

Sail thus obtained is extremely light (the reinforcements are formed by the joining of fibers and not by overlapping material as in paneled sails) and high-performance: the macro panels designed with the camber where necessary, fibrates as project and the few joints make sail a true wing.